According to most air conditioner experts, there are three basic maintenance items for AC units that people overlook. And these three items comprise a large portion of easily preventable equipment failures. These consist of the condensate line, the air filter, and the condensing coil.

The Condensate Line

In Texas, most single-family homes with AC have what’s called a split system. This consists of a big box that sits on top of the furnace called an evaporator coil, which is connected to another box at the exterior that contains the compressor and condensing coil. If you’re curious about how this system works, head to HowStuffWorks; they have some nice descriptions and illustrations.

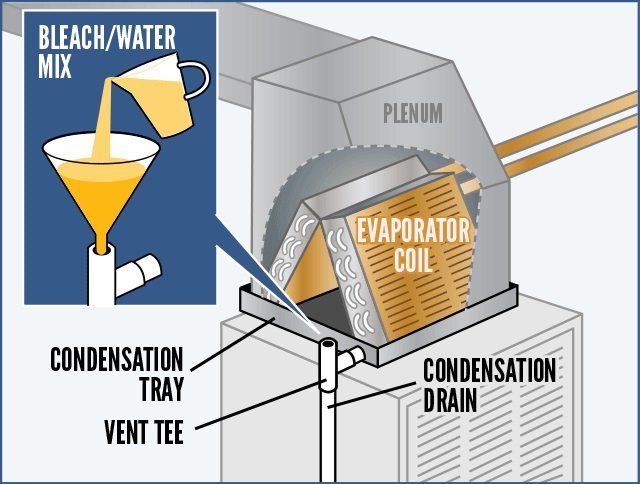

An air conditioner ‘conditions’ the air by removing heat and moisture. As warm, moist air gets passed over the evaporator coil (the thing that sits above the furnace or air handler), moisture condenses on the cold tubing. This condensate drains down to a pan where it gets directed out.

Condensate needs to be directed to an appropriate location, which is typically a nearby floor drain (i.e. sink or washing machine drain). This drain material must consist of cast iron, galvanized steel, copper, copper alloy, PEX, polyethylene, ABS, CPVC, PVC, or polypropylene pipe or tubing. The drain must also have an internal diameter of at least 3/4″.

When improper materials are used, the drain is undersized, the condensate drain has an increased potential to get blocked up. If the condensate drain consists of a garden hose or clear plastic tubing, replace it. This will help to prevent a blocked condensate drain, which will help prevent unwanted leakage at the evaporator coil.

Make sure your condensate drain is properly installed and properly secured.

In addition to this, there is a P-Trap in the condensate line typically in the attic near the air handling unit. Once a year you should pour a cup of bleach or vinegar in this to prevent organic growth that may plug your drain line during extended periods when you are not operating your AC unit (i.e. winter). I usually add vinegar to my condensate drain line vent over the Thanksgiving break each year. I prefer vinegar as it is more environmentally friendly than bleach.

The Air Filter

The air filter, also known as the furnace filter, must be replaced regularly. Usually, every one to three months will do, depending on the type of filter that’s installed. While most homeowners know about changing the filter during the winter, this still needs to happen during the summer when the AC is running.

If your home has a high-velocity system with an air handler in the attic, the filter will usually be located at the ceiling in an upper-level hallway, bedrooms, or in the attic right before the air handler unit.

Restricted airflow means reduced efficiency and reduced cooling capacity.

The Condensing Coil

This is the one that gets forgotten about the most. The compressor and condensing coil are the parts that sit outside the home, preferably in some out-of-the-way part of the yard. To help dissipate the heat that gets removed from the home, a big fan pulls outdoor air over the condensing coils.

For the condensing coil to work properly, it needs plenty of airflow. This means no trellis attached to it, no ivy, no plants, no walls, no boxes, and so on. Clearance requirements will vary from manufacturer to manufacturer, but a good general rule is 24″ of clear space. Keep vegetation trimmed away.

Condensing coils also need to be cleaned regularly. If your condensing coil is covered with dirt, dust, grass clippings, dryer lint, cottonwood seeds, and other outdoor stuff, you won’t have good airflow. Take the time to inspect all sides of the unit and clean the coils off if necessary. This can usually be done by spraying the unit down with a garden hose. Don’t try a pressure washer; the fins will bend very easily.

If your unit has protective grills that prevent access to the coils, you’ll need to take the grills off first. At that point, you need to do some dismantling. You might prefer to have an AC technician do the work if that’s the case.